Energy Drinks – Part 2

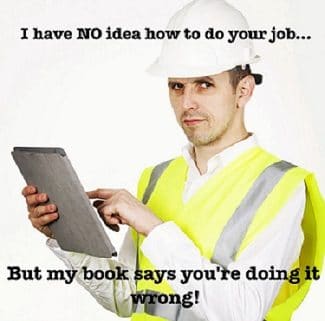

I find it hard as a consumer to know what I’m getting into with these drinks. Lots of them have added vitamins and therefore marketed as “health drinks” or they add ginkgo biloba and it’s marketed as making your mind sharp. Not to mention there are a million studies both for and against these drinks. One argument is that your healthy allowable amount of caffeine is a whopping 400mg a day and energy drinks are around 100-800 mg. So that makes some of them safe right?……Unfortunately, this may not be so. Sadly, the WHO (World health organisation) studies against energy drinks have one thing to support their argument that the others don’t… Stats on hospital visits and deaths. In Canada, we do have some regulations on energy drinks, but there is still definitely some gray area. Some drinks fall into different categories such as the energy shots that can have as much as 800mg of caffeine in one mouthful shot. Also, mixing any of these drinks with alcohol is a huge no-no, but still allowable in most places in Canada. There are still no regulations on these drinks being sold to children.

So, I guess what I’m saying is know your stuff, educate yourself on the risks. If you already have a heart condition, definitely do your research and talk to your doctor. One now and then is probably safe if you’re healthy, but given the controversy, I’d recommend always playing it safe. So, does this mean we just fall asleep at work? No, instead try getting more sleep at night, regular exercise and a healthy diet. I know it’s not a quick fix but hey neither is a heart attack?