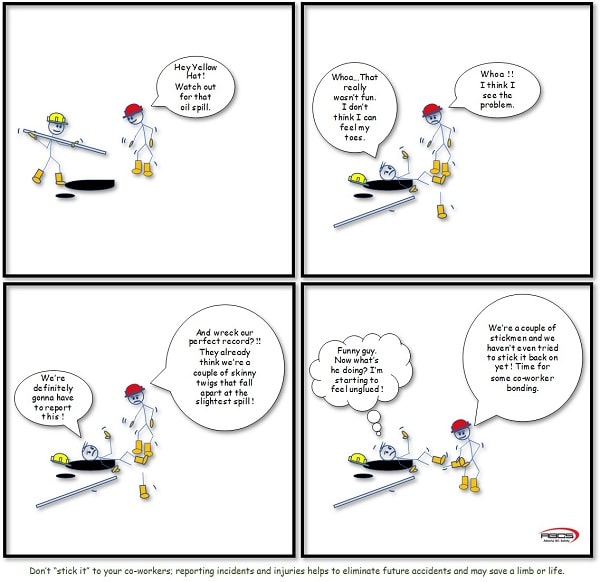

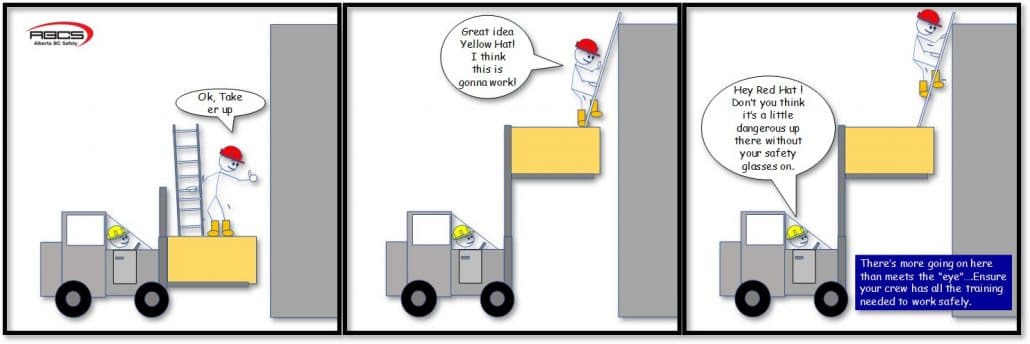

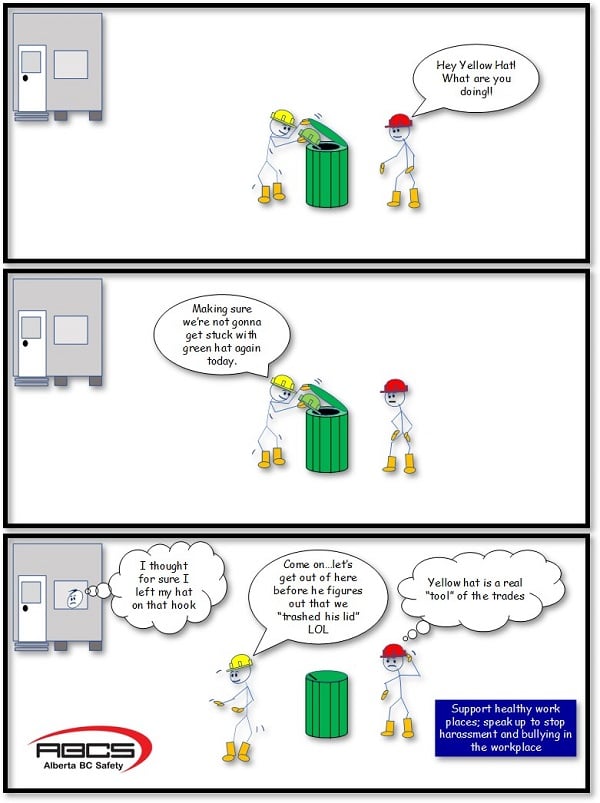

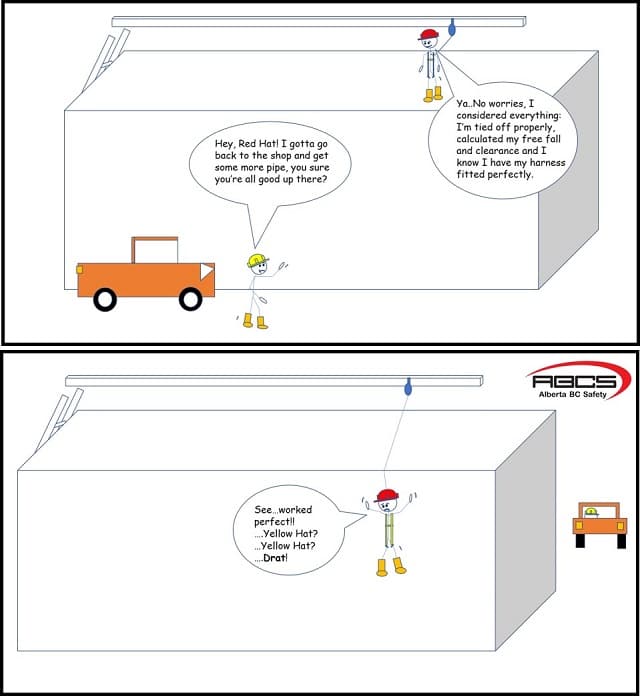

The Importance of Reporting Incidents

No matter how small you may think an incident is, you need to report it. This isn’t you being a “company worker” or a “rat”. This is you looking out for yourself and your coworkers. There is a misconception that you will be fired upon reporting an incident. However, you will be more likely to be let go if your employer finds out later that you hid the incident and didn’t report it. Not only does your employer have a legal obligation to report all injuries (anything more than on site first aid) to the Worker Compensation Board within 72 hours of it happening, but the quicker your case is sent in, the quicker you will see compensation, if you need it. Even if you think it’s something small, and you don’t report it and it turns out to be a serious injury, WCB will not receive claims in Alberta after 24 months. Even then, there has to be certain circumstances that they will allow a claim that long after an injury. So by reporting any injuries, you are covering your own butt and making sure you’re at least covered by WCB if things go sideways. Not to mention, reporting near misses and incidents is how we learn. Sadly people had to fall from heights to make fall protection the standard, workers lost their eyesight to make safety glasses mandatory and so on and so on. So you reporting an incident could ensure an investigation that leads to the problem being solved; thereby, saving the next worker from injury or death. If that’s not looking out for your work buddies, I don’t know what it is.