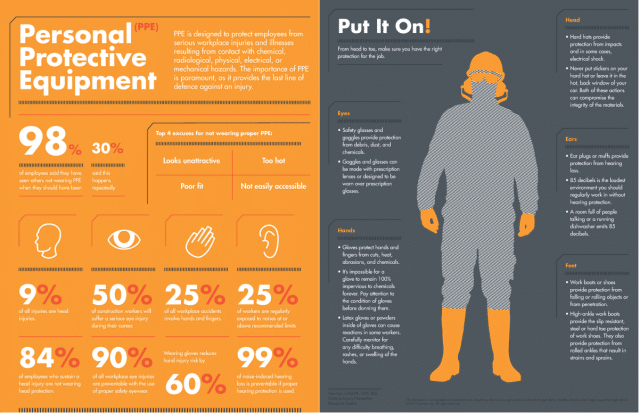

In oil and gas industry production managers face many challenges concerning personal protective equipment (PPE) compliance. PPE is designed to protect and prevent workplace injuries. It can include items such as hard hats, gloves, eye protection, footwear, harnesses, etc.

Employers are responsible for providing and enforcing the use of personal protective equipment. Also employers must ensure that appropriate PPE is identified and being used by workers. Workers must be trained in the use of PPE prior to use.

Head Protection

Hard hats need to be CSA approved and meet site standards. When using a hard hat inspect it regularly, don’t paint it, don’t use it if it has a crack or deep gouge and keep it clean.

Don’t forget neck protection, eg scarves for use during welding.

Wearing earplugs or earmuffs can help prevent damage to hearing. Exposure to high noise levels can cause irreversible hearing loss or impairment as well as physical and psychological stress.

Foot Protection

Boots must protect ankle, sole, toes and meet CSA and site standards. It is worker’s responsibility to keep boots in good condition and keep laces tied up at all times to avoid tripping.

Eye Protection

Make sure the eye protection has the right combination of impact/dust/splash/molten metal eye protection for the task and fits the user properly.

Hand Protection

Avoid gloves when operating machines such as bench drills where the gloves could get caught. Mandatory in operating and maintenance areas.

Wristlets are used to reduce contact with hot materials between gloves and sleeves.