Safety Training

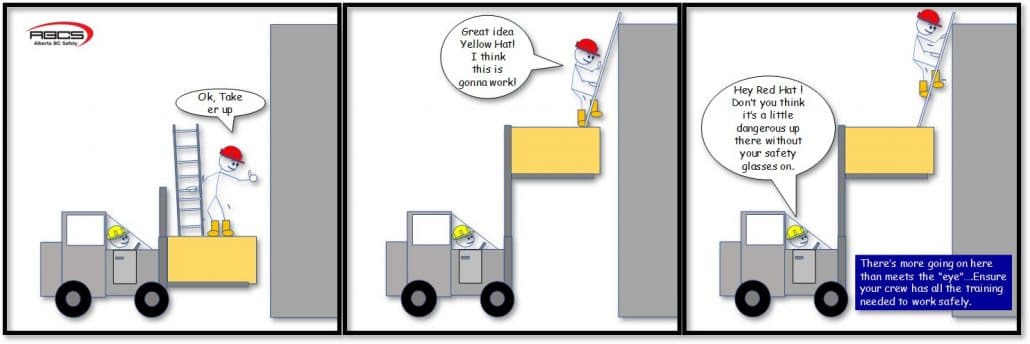

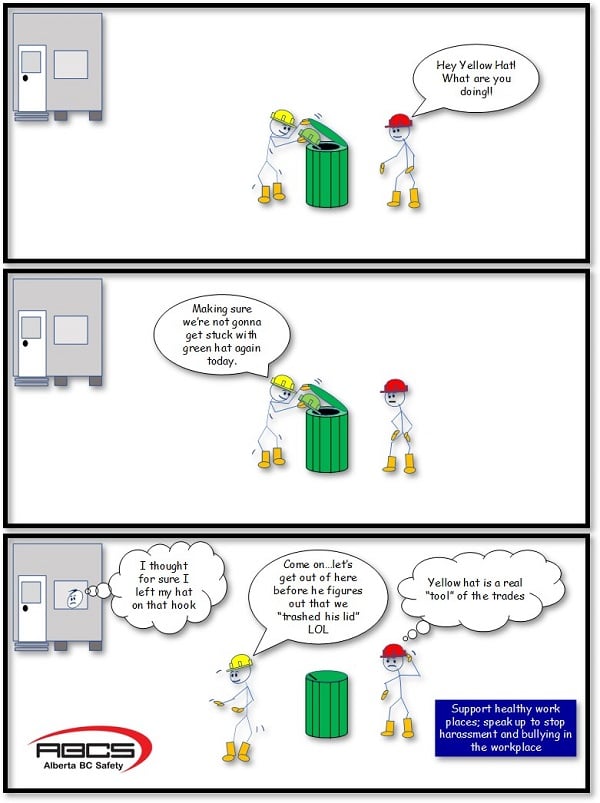

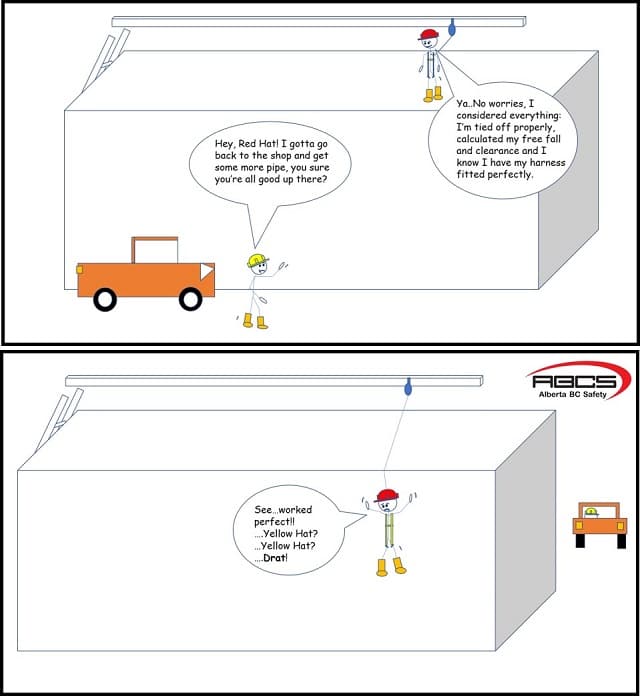

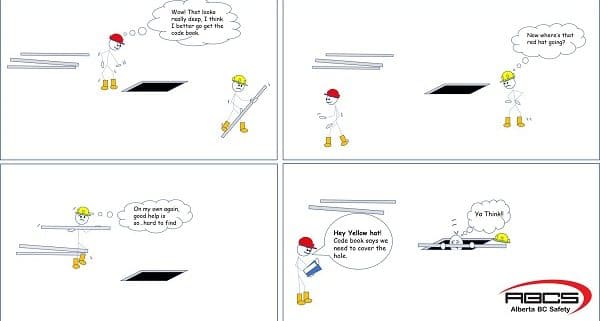

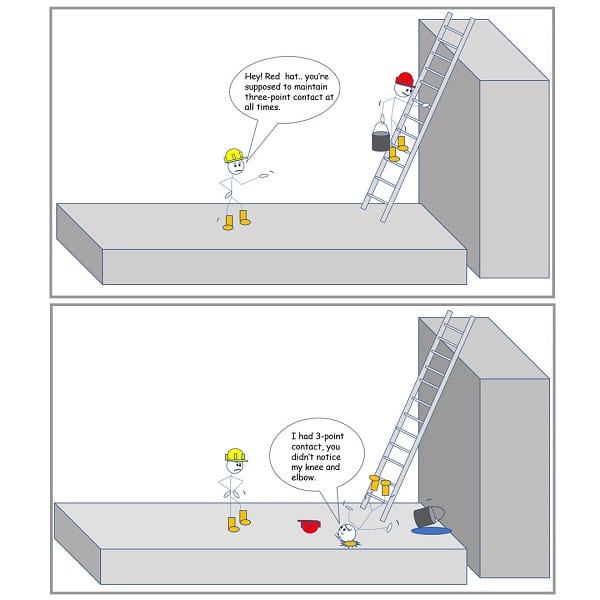

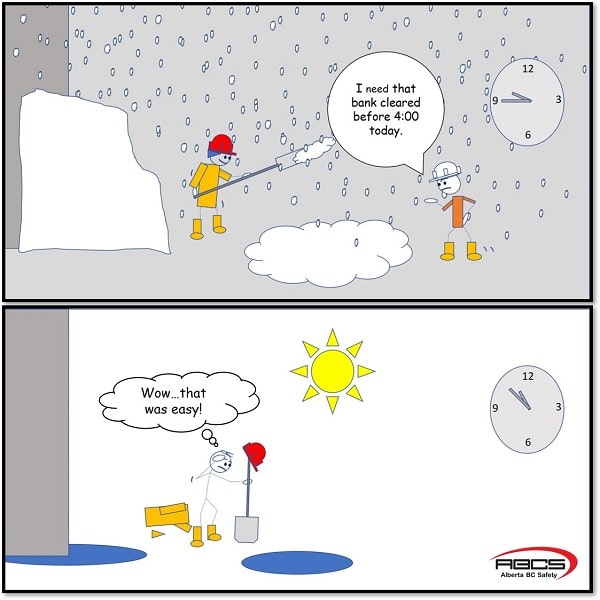

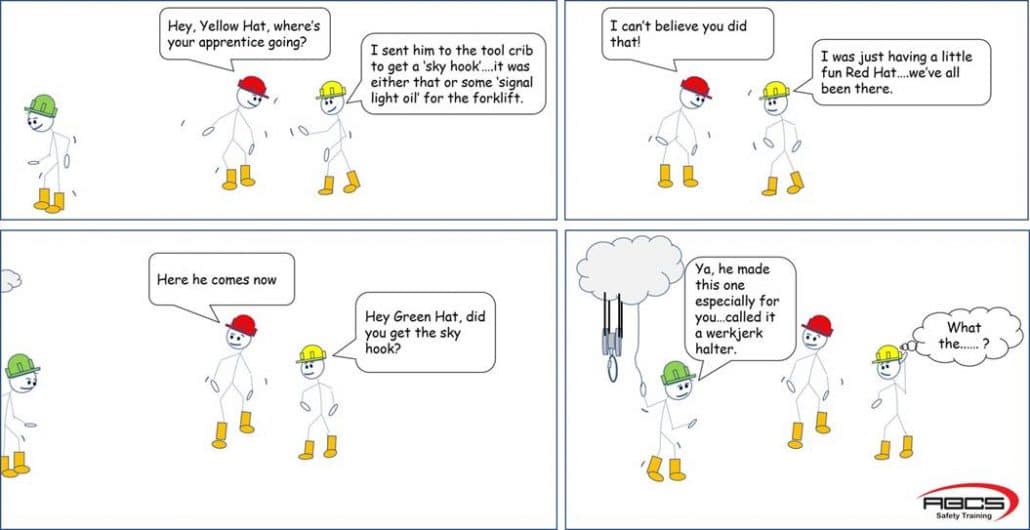

Training isn’t just to show you the ropes when it comes to your trade, how to hammer a nail, tighten a bolt, or bend some tubing. Safety is a huge part of your job too. Safety training provides us with opportunities to learn from the mistakes of others. We all need to learn the safe way to do our daily tasks. You may be the most skilled worker at a specific task, but if you take risks and put yourself or others in danger, those keen skills may never see the light of day. Safety training, safe work procedures, and safety programs are the reason we all get to go home to our families every night. It’s the reason we get to work our entire careers until we retire, instead of trying to make ends meet with disability cheques because of an injury. It’s the reason we know our rights as an employee and what we can expect from our employers. Without proper safety training, situations like this cartoon would be an everyday occurrence. So, I guess what I’m saying is, safety training and programs are increasing the life expectancy of us trades people. We are living longer than 30, 20 or even 10 years ago. So, let’s make sure we have all the training we need to do our trade safely, keep up-to-date on new innovations, and keep a good attitude when it comes to safety training. And please for love of all things good, do not risk your life for your job. Don’t be Mr. Red Hat. 🙄